This video reminds us of the popular video showing how to convert Salt Water into Fuel, which is not practically easy and profitable – as the process consumes more energy than it produces.

Although the present story sounds too good to be true, it holds up to scrutiny and does not violate any physical laws.

Yes, it is a fact that plastics are generally recycled back into oil in massive facilities, and this is possible because most of the plastics today are made from oil.

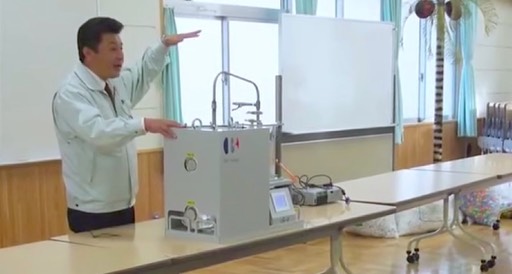

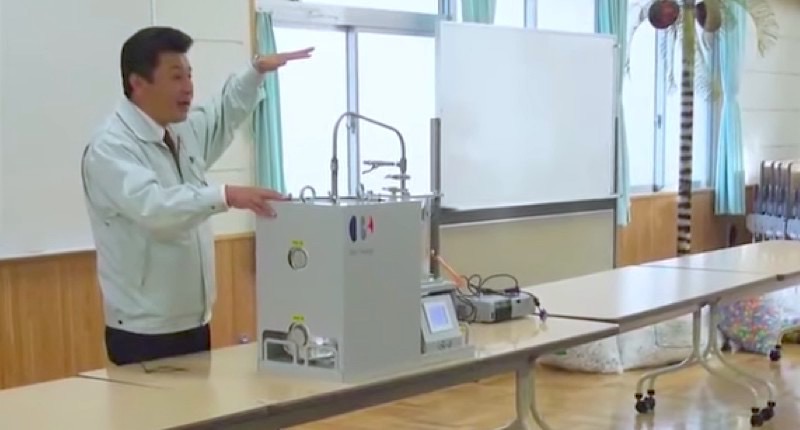

The Japanese inventor here, Mr. Akinori Ito has in fact built a tabletop machine called "Blest Machine" which can do the same task safely and cleanly.

There are several companies across the world that are trying to make this process profitable.

Agri-Plas, an Oregon-based plastics recycler company, is the first one in U.S to convert unwanted and typically unrecyclable agricultural plastics into crude oil.

The company has even shipped this oil to a…

refinery for commercial processing. Then there are other companies like Agilyx (formerly Plas2Fuel), the Envion Oil Generator, and few others that you can read from the reference section below.

Pyrolysis

Pyrolysis is a thermochemical decomposition of organic material at elevated temperatures without the participation of oxygen. This involves simultaneous change of chemical composition and physical phase.

In present case, as explained in the video below, the plastic waste is heated at high temperatures to decompose and convert into oil and other by products, which can be used as fuel.

The Blest’s conversion technology uses a temperature controlling electric heater, inside which the machine can process polyethylene, polystyrene and polypropylene.

The machine gives a crude gas that can fuel things like generators or stoves and, when refined, it can also be pumped into a car, boat or a motorbike.

When this gas is cooled down, it produces oil, which can again be refined for using in various ways.

Depending on the quality of plastic, the machine can convert 1 kg plastic to about 1 liter of oil. Reports suggest that this process of converting waste plastic into oil is a good deal as well.

The Blest company also has a refiner machine for separating hydro carbon oil from this crude oil, which converts this mixed oil into Gasoline, Kerosene, Diesel oil and heavy oil equivalents.

Only time and development in these technologies will tell us how efficient, safe and profitable these conversion processes can be.

Sources:

Japanese ‘Blest Machine’ recycles plastic into oil at home

Plastic to oil fantastic

Agri- Plas ships first batches of crude oil to refinery

Tomorrow’s fill-up could come from plastic waste